Aligning supply and demand plans has proven difficult for many organisations, resulting in failure of key operational and financial metrics.

Solving the supply requirements for demand is a complex problem when seeking an optimal or feasible answer. Developing the correct response to demand is a significant undertaking when various attributes such as demand, inventory, production orders, purchase orders, bill-of-materials, process, planning policies, lead times, etc., are considered. These attributes form numerous combinations and permutations to solve the complex demand-supply question based on defined objectives.

Around 60% of companies are still using complicated and bulky spreadsheets or antiquated and slow systems to address this need. The results are, at best, less than ideal, resulting in poor performance of fulfilment, inventory, revenue, and margin, as well as a lot of firefighting within lead times.

Vuealta’s response to address the need for a robust and fast solution to the demand-supply question is “Vuealta Production Planning”, powered by the Anaplan platform. Providing this capability complements the implementation of demand planning on a single platform. As part of Vuealta’s core Supply Chain Planning solutions, Production Planning is offered within the Supply Planning suite. It can be implemented with the full suite of solutions for an end-to-end deployment or independently in a stand-alone mode.

Leverage optimization for best-in-class Production Planning

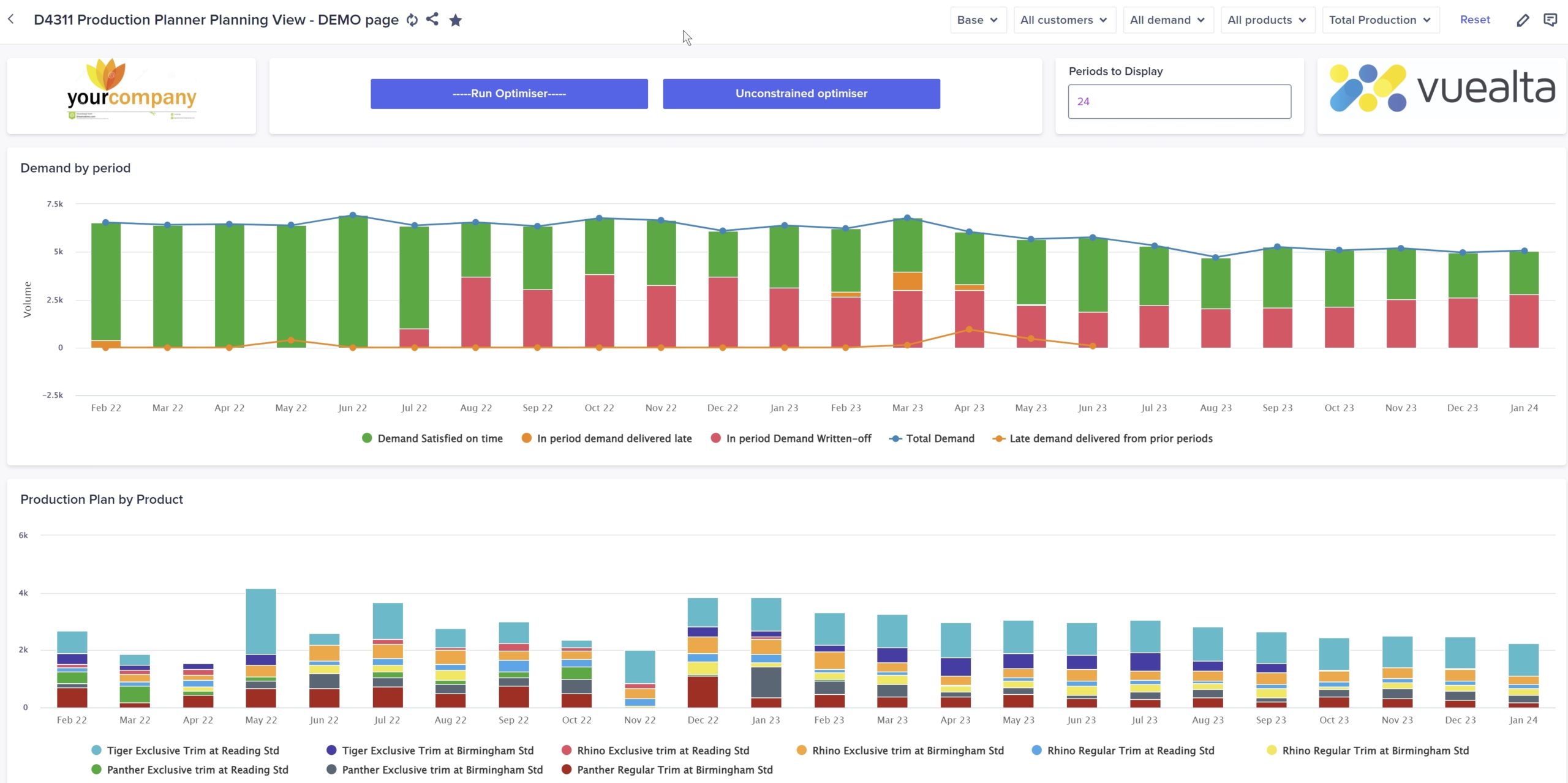

Bringing speed, intelligence and reality to the demand plan is where Vuealta Production Planning changes the game. Leveraging the fastest and most powerful mathematical programming solver available, Anaplan Optimizer, Vuealta Production Planning computes the optimal plan based on the combinations and permutations of the planning data. Using defined goals or objectives, drive the desired production and financial outcomes based on stated constraints.

For instance:

- Develop an optimal plan based on revenue, margin, or demand priorities (customer, due date) while respecting material and capacity constraints.

- Ensure that demand is fulfilled based on their priority and revenue expectations.

- Maximize resource utilization while ensuring lean material levels.

- Identify resource bottlenecks for remedial action to address order lateness.

- Determine any material shortages so that they can be filled or expedited.

- Based on the optimal plan, generate planned production and purchase requirements recommendations, which can be fed into the ERP system for execution.

Perform all the above tasks and processes automatically, and within seconds.

See the Demand Fulfilment Product Screenshot below to get a better idea of how our solution work.

Model Scenarios to understand the operational & financial impact of your Production Plan

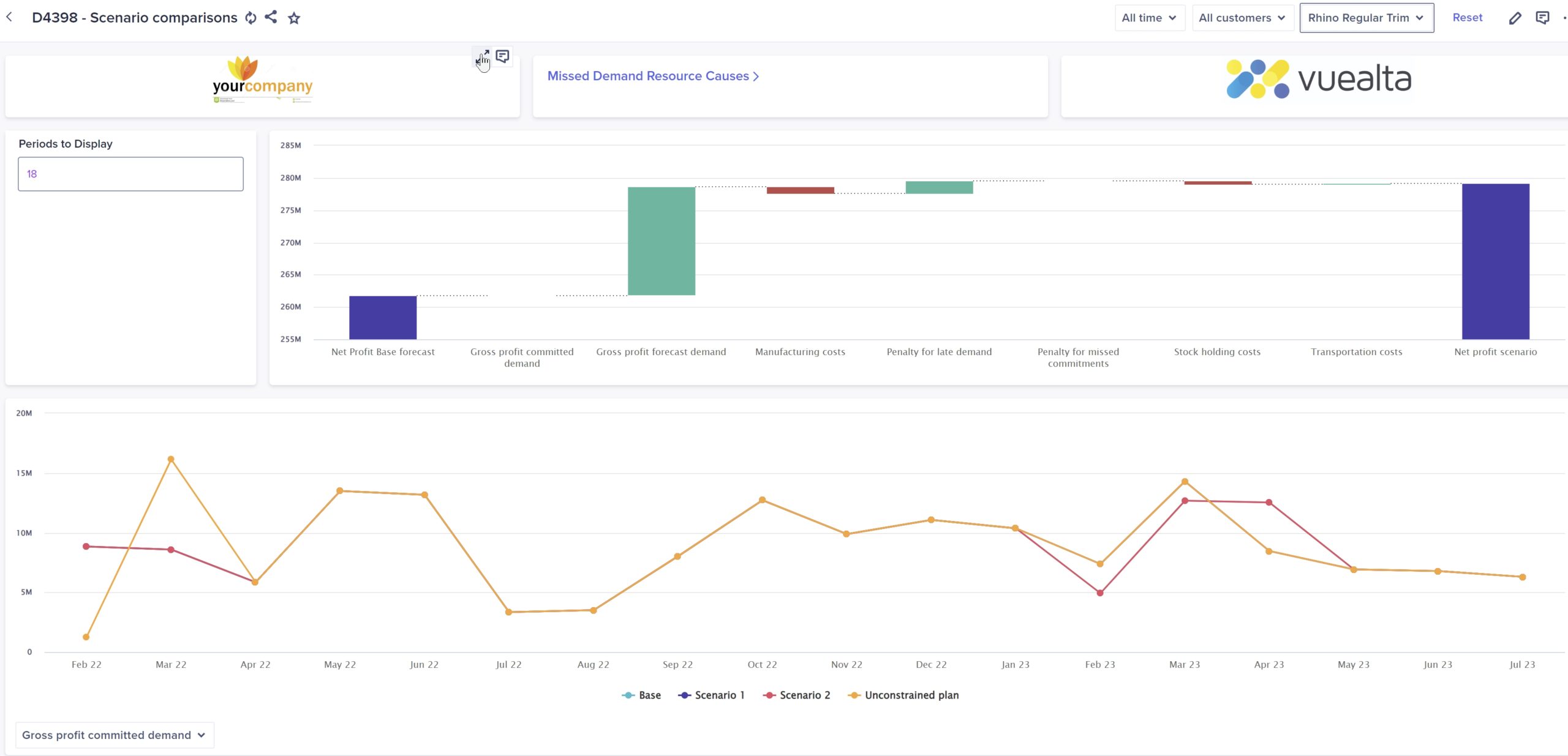

Quite often, disruptions happen within the supply chain and planners need to react with realistic and accurate decisions. Before making any tactical changes to your current manufacturing decisions on what could be, wouldn’t it be insightful to know the impact?

In many situations, planners would like to know the implications of changes to the current plan before committing any final decisions but are unable to do so. They are not able to get an accurate picture of order lateness, capacity or material issues, or even financial impact on revenue and margin. This leads to best guesses which often yields undesired and poor results.

Addressing this situation is the powerful scenario modeling capability within Vuealta Production Planning. Planners can define a scenario to simulate changes in demand, inventory, capacity, material, objectives, etc., and understand the operational and financial impact. These scenarios can be performed as many times as required with different assumptions. The results of these scenarios can be compared side by side with the base plan and evaluated for the best option. Based on the results of each scenario, the preferred version assumptions can be implemented to the current plan as the new base.

Check out the Scenario Comparison screenshot below.

Informed executive decision-making

As part of the Executive S&OP process, executives are required to review the business performance and plan ahead. Executives making critical decisions for their organisations frequently rely on outdated or inaccurate information. Largely, this is primarily due to dated systems, which are not connected using manual processes. Vuealta Production Planning is an integral part in providing real-time and accurate information which executives use for effective decision making. They no longer need to “fly blind”.

A common use case is when executives need a view into the future direction of the business so they can effectively plan and allocate the necessary resources.

For example:

If the business is expected to grow its revenue by 20% year over year, what operational investments such as manufacturing resources (assets, people), are required to support this growth rate?

A scenario can be used to simulate this growth expectation, to determine the capacity and material requirements in the unconstrained mode. This will provide an overview of the resource utilization and highlight the key bottlenecks for investments consideration. Additionally, these kinds of insights can be obtained even in the current operating year for agile decision making.

Operational excellence by optimal planning

So, the good news is no more guess work in planning your supply to drive value within your supply chain. No more reliance on complicated spreadsheets, dated applications or even ERP/MRP systems. No more unexpected surprises on the production outcomes. Vuealta Production Planning will optimize your planning for improved operational and financial performance, with positively impacting key metrics such as customer service, revenue, margin, inventory levels, resource utilization, and so on. You can confidently commit supply over the planning horizon while meeting organizational goals and ensuring high customer satisfaction.

Maintaining operational excellence requires the ability to perform “what-if ” scenarios across the supply chain. As disruptions to the current plan may happen, having the ability to model the situation and determine the impact is critical. Vuealta Production Planning powerful scenario modeling considers key constraints and objectives to give provide optimal answers. Ultimately, generating realistic answers for effective decision making to provide excellence in service.

Learn more about best-in-class Production Planning

Vuealta Production Planning was designed and built by Vuealta Product Engineering using the Anaplan Optimizer, which is fast and scalable. It sits on the Anaplan platform and is fully integrated with other solutions in Vuealta’s Supply Chain Planning suite. It can be readily implemented as part of the end-to-end Vuealta SCP solution deployment or in a stand-alone mode, integrated with other applications.

For more information on how Vuealta Production Planning can support your planning requirements and bring value to your organization, please click on the link below to watch a short demo. Alternatively, please contact Vuealta, to speak with a Supply Chain expert about your specific needs for your organization and discover how we can help.